“You’re moving in next week ?” said Jill, my trusted move-in/move-out house cleaner as we toured the new place. Looking at the paint splattered floors, unmoored broken appliances and piles of wood shavings, I understood why she thought that seemed iffy. Would the house be ready in a little over a week for us to move in? I felt a little better the next day when William Anderson showed up to help pick the final floor color a month after he’d first seen the house. “Everything looks great—you’ve done so much!” he exclaimed.

“You’re moving in next week ?” said Jill, my trusted move-in/move-out house cleaner as we toured the new place. Looking at the paint splattered floors, unmoored broken appliances and piles of wood shavings, I understood why she thought that seemed iffy. Would the house be ready in a little over a week for us to move in? I felt a little better the next day when William Anderson showed up to help pick the final floor color a month after he’d first seen the house. “Everything looks great—you’ve done so much!” he exclaimed.

Yes, yes we have. The new house is still very much a construction zone, but through the haze of drywall dust I can see what a lovely home we’re making. Here’s some of what transpired over the last week and a half.

In the kitchen we analyzed the cabinetry to figure out what could and couldn’t be modified so we could order our new appliances. For example, the existing cooktop is ventilated with a downdraft. It would be a major undertaking to add a ventilation hood to the kitchen, but also some work to incorporate a beefier downdraft. We’d need to modify the pullout drawers beneath the cooktop, which would mean that my 12″ skillet couldn’t live there comfortably. So for now, we’re sticking with what we’ve got ventilation-wise and hope it’s enough.

However, we opened up the refrigerator box to make way for a cabinet depth refrigerator as well as the original pantry cabinet. Yes, I know it looked this way in my last post. You can see why Jill’s a little skeptical about our timing.

Gustavo worked on the defective copper tubing that feeds the refrigerator icemaker but called in William the plumber to install the new faucet and InstaHot–something I didn’t think I needed until I had one in my last house and missed it so much in our rental that I decided to forgo the sink soap dispenser and put one in its place.

While he was there, William the plumber (not to be confused with William the decorator or Bill the electrician or Willie the floor refinisher) also moved the powder room sink pipes over a few inches to the center of the room. Then he worked with Gustavo to cut out an opening behind the existing washer and dryer so the appliances could be inset into the laundry room wall and not jut out two inches into the opening of the adjacent storeroom. Another example of little things making a big difference.

While he was there, William the plumber (not to be confused with William the decorator or Bill the electrician or Willie the floor refinisher) also moved the powder room sink pipes over a few inches to the center of the room. Then he worked with Gustavo to cut out an opening behind the existing washer and dryer so the appliances could be inset into the laundry room wall and not jut out two inches into the opening of the adjacent storeroom. Another example of little things making a big difference.

We’d been warned that the washer also leaked, but hopefully with new hoses attached that problem is solved. And look at the nice new floor covering–a remnant of white hospital grade vinyl that M.J. found at Anderson Carpet and Linoleum. “We could do surgery in here,” says M.J. Top of my list, honey.

We’d been warned that the washer also leaked, but hopefully with new hoses attached that problem is solved. And look at the nice new floor covering–a remnant of white hospital grade vinyl that M.J. found at Anderson Carpet and Linoleum. “We could do surgery in here,” says M.J. Top of my list, honey.

Gustavo spent many hours reconfiguring door openings and hanging doors. Here’s the new entry closet door–remember the utilitarian bi-fold doors that were there before? We closed up the closet opening just a bit so the closet door was the same distance from the front door as the garage door to create a pleasing symmetry on the entry wall. Then we replaced the garage, closet and powder room paneled fir doors with solid doors that will be painted Swiss Coffee like the walls so that they mostly disappear.

Gustavo spent many hours reconfiguring door openings and hanging doors. Here’s the new entry closet door–remember the utilitarian bi-fold doors that were there before? We closed up the closet opening just a bit so the closet door was the same distance from the front door as the garage door to create a pleasing symmetry on the entry wall. Then we replaced the garage, closet and powder room paneled fir doors with solid doors that will be painted Swiss Coffee like the walls so that they mostly disappear.

All the doors on this level now have more modern hardware–Helios by Emtek.

The Miracle Method guys spent a couple of days spiffing up the master bath shower and guest bath tub. In my dream house I have a beautiful deep freestanding tub, but for now I’m just grateful to have one that isn’t significantly gouged and scratched on the edge.

In hopes of finding a replacement handle for the shower, I visited several plumbing vendors. Turns out this handle and likely the others in the house are from Moen.

I didn’t have any luck yet finding an attractive replacement kit, so I’m still on the hunt.

I didn’t have any luck yet finding an attractive replacement kit, so I’m still on the hunt.

Along the way I saw these cool pipes at Emperor Supply and this jaunty shark sign at Moran Plumbing. I like to think about sharks in my plumbing pipes–don’t you?

Along the way I saw these cool pipes at Emperor Supply and this jaunty shark sign at Moran Plumbing. I like to think about sharks in my plumbing pipes–don’t you?

The same day the refinishers were finishing up in the bathrooms and Gustavo was hanging doors, Bill from Early Light Electric showed up to tackle a laundry list of small items–in the laundry room and elsewhere! He modified an old track lighting box so we could hang our West Elm capiz shell chandelier in the dining room, got the other bathroom and laundry room fans running, installed lights in some of the storage areas and put junction boxes for two yet-to-be-purchased sconces in the powder room. Here’s his truck along with the rest of the workmen’s fleet in the driveway. Holy Moly, we were cooking with gas that day!

The reason everyone showed up All At Once was because we decided to do the floors after all. I initially thought we could live with them as they were since they’d just been refinished to sell the house, but the color kept bugging me. The red oak planks had been covered with an amber stain that made them turn orange–not a good match for the white-washed ceilings and kitchen cabinets. And frankly, the job wasn’t all that good. Nail heads peppered the floors and looked streaky in spots. We knew we had to have several areas repaired but was it economical or ethical to also redo newly refinished floors?

“You’ll never do them again if you don’t do it before you move in,” said my sisters and friends. ”If you can stretch at all, this would make such a difference visually,” said the pros–William the decorator and Steve the painter. Finally convinced, I searched for a recommended floor refinisher that could work with our rapidly approaching move-in date and ended up hiring Amber Flooring in Emeryville.

“You’ll never do them again if you don’t do it before you move in,” said my sisters and friends. ”If you can stretch at all, this would make such a difference visually,” said the pros–William the decorator and Steve the painter. Finally convinced, I searched for a recommended floor refinisher that could work with our rapidly approaching move-in date and ended up hiring Amber Flooring in Emeryville.

It was tricky to choose a color from the many lovely samples in the showroom. I knew I was looking for something on the coolish side, but was tempted by that hot red.

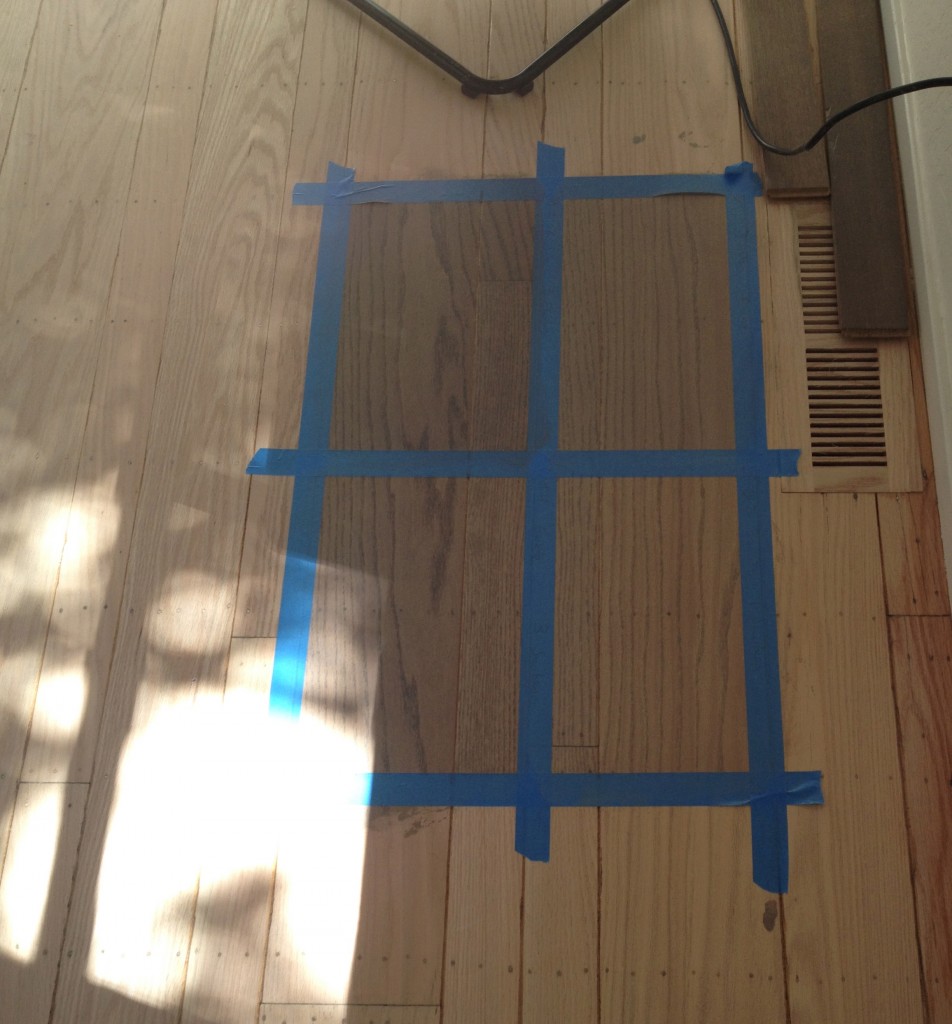

Regaining focus, I settled on something in the medium gray range after William showed me some planks from another project he’s working on. Here are some samples painted on the floors after they’d been stripped. We ended up choosing the sample on the upper right–3 parts white wash to 1 part Ebony–because it looked best with the kitchen cabinets close up and therefore we assumed would work well with the similarly whitewashed ceilings above.

I was surprised at how battleship gray the stain is when it’s first applied, but then it quickly turns a more ashen/bronzed gray as it soaks into the wood.

I was surprised at how battleship gray the stain is when it’s first applied, but then it quickly turns a more ashen/bronzed gray as it soaks into the wood.

Today, all work ceased in the house as we waited for the stain to cure. This is what I saw standing outside on the deck as I–yes–watched the paint dry. It was a lovely, calming sight. NOTHING else can be done here for the next few days. Which means I can stop running around and go pack. Because, yes, we are moving in next week.

Today, all work ceased in the house as we waited for the stain to cure. This is what I saw standing outside on the deck as I–yes–watched the paint dry. It was a lovely, calming sight. NOTHING else can be done here for the next few days. Which means I can stop running around and go pack. Because, yes, we are moving in next week.